Sales manager:Tom Zhan

Tel:+0086 13632658537

Skype: zxp94520181

Whatsapp :+86 13632658537

Wechat: zxp94520181

Email:tom.zhan@primeda-telecom.com

www.primeda-telecom.com

Feature:

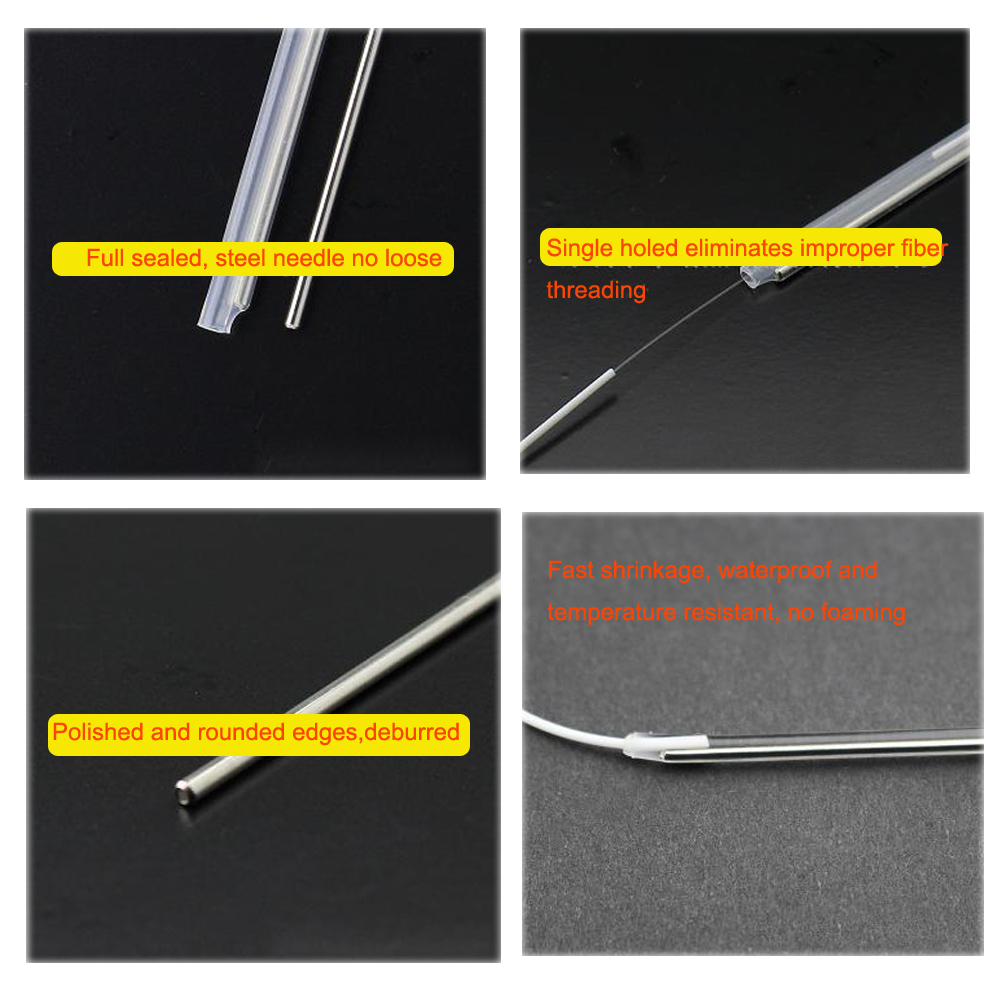

1. Comptact design, Clear sleeve make it easy to detect splice before shrinkage

2. Airproof structure keeping the splice point's good resistance of humidity and temperature

3. Strength member is made from "Full hard" stainless steel of 304 grade and is ground at the edges before polishing to make it completely burr free to avoid rupturing during shrinking. 304 grade gives better corrosion resistance, even in coastal environment. Resistant to heat shocks, no cracking dripping or flowing

4. Easily use and avoid any damages to the optical fiber during installation

Specification:

| Mirco type Fiber Optic Fusion Splice Protection Sleeves |

|

| Part No. | L | Lp | D(OD after recovery) | Dp(Steel needle OD) | d(Hole ID before recovery) | Steel needle grade | Color | Regular stock |

| PMD-45D | 45 | 44 | 1.4+/-0.1 | 0.5 | 0.5+/-0.1 | 304 | clear | √ |

| PMD-40D | 40 | 39 | 1.4+/-0.1 | 0.5 | 0.5+/-0.1 | 304 | clear | √ |

| PMD-35D | 35 | 34 | 1.4+/-0.1 | 0.5 | 0.5+/-0.1 | 304 | clear | √ |

| PMD-30D | 30 | 29 | 1.4+/-0.1 | 0.5 | 0.5+/-0.1 | 304 | clear | √ |

| PMD-25D | 25 | 24 | 1.4+/-0.1 | 0.5 | 0.5+/-0.1 | 304 | clear | √ |

| PMD-15D | 15 | 14 | 1.4+/-0.1 | 0.5 | 0.5+/-0.1 | 304 | clear | √ |

| PMD-25G | 25 | 24 | 1.3+/-0.1 | 0.4 | 0.4+/-0.1 | 304 | clear | √ |

| PMD-45E | 45 | 41 | 2.2+/-0.2 | 0.8 | 1.3+/-0.2 | 304 | clear | √ |

| PMD-45F | 45 | 44 | 1.9+/-0.2 | 0.7 | 1.2+/-0.2 | 304 | clear | √ |

| PMD-40F | 40 | 39 | 1.9+/-0.2 | 0.7 | 1.2+/-0.2 | 304 | clear | √ |

Remark:

Special size available to custom made. All dimensions in mm.

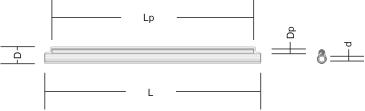

L - Length after recovery

Lp - Pin length

D - Outer diameter after recovery

Dp - Steel Pin diameter

d - Hole diameter before recovery

Packing: 100pcs or 200pcs per bag.

MATERIAL SPECIFICATION

1. Application Type: Single Fiber 250µm

2. Compatibility: Most splice trays, ovens and coated fibers

3. Outer Material: Cross-linked Polyolefin Heat Shrinkable Tubing +135°C MIL Spec.

4. Inner Material: Hot-melt adhesive Ethylene Vinyl Acetate (EVA) Copolymer

5. Reinforcing Pin: Stainless Steel 304 with polished and rounded edges

6. Colours: Clear for easy visual inspection

7. Splice Operating Temperature: -40°C to +70°C (Heat shrink outer rated at -55°C to +135°C)

8. Storage Temperature: -40°C to +70°C

9. Package Quantity: Bags of 100pcs or 200pcs.

Description:

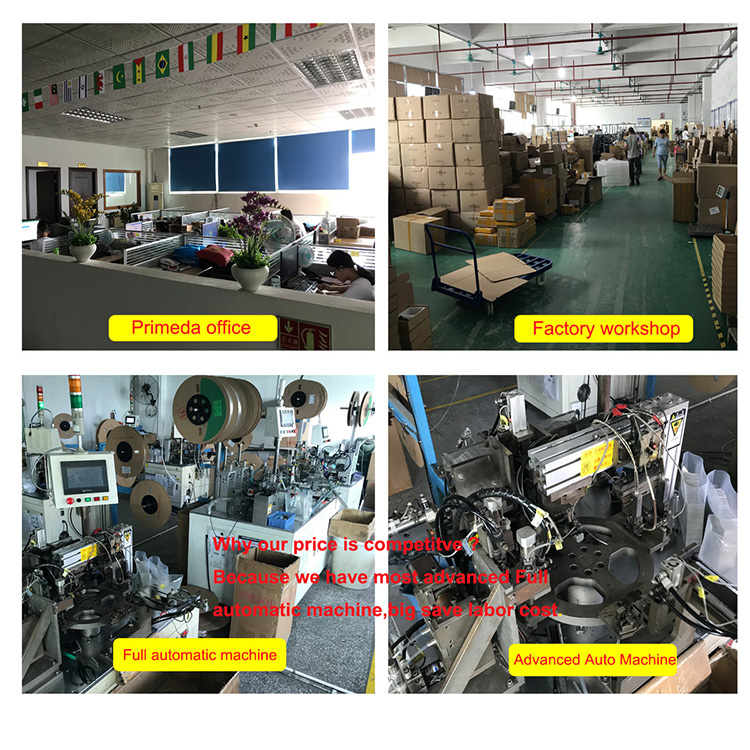

1. High quality and reliability with Industry Standard

2. Specialist Manufacturer with 15 years proven reliability

3. Single fiber entry hole for faster installation

4. Encapsulated reinforcing pin

5. UL Approved high quality materials

6. Compatible with most fibers, splice trays and ovens

7. Over one Million GT/PMD series held in stock