Sales manager:Tom Zhan

Tel:+0086 13632658537

Skype: zxp94520181

Whatsapp :+86 13632658537

Wechat: zxp94520181

Email:tom.zhan@primeda-telecom.com

www.primeda-telecom.com

Specifications:

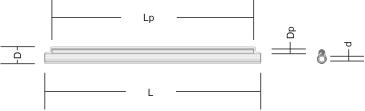

- 1. Whole length: 61mm (40/45/55/61mm optional)

- 2. Outer diameter after recovery: OD2.5 mm +/- 0,1mm

- 3. Hole diameter before recovery: OD1,3 mm

- 4. Stainless steel needles diameter: OD 1.2 mm (1.0mm/1.2mm/1.5mm optional)

- 5. Minimum installation(shrinking) temperature: 110°C

- 6. Max installation time: 60 seconds

- 7. Standard color: Clear

- 8. Low Temperature property: No crackle at -55°C lasting 4 hours

- 9. RoHS compliant

- 10. Packing: 100 pcs per bag (Others for special order)

Features:

- 1. Clear sleeve make it easy to detect splice before shrinkage

- 2. Airproof structure keeping the splice point's good resistance of humidity and temperature

- 3. Strength member is made from "Full hard" stainless steel of 304 grade and is ground at the edges before polishing to make it completely burr free to avoid rupturing during shrinking. 304 grade gives better corrosion resistance, even in coastal environment. Resistant to heat shocks, no cracking dripping or flowing

- 4. Easily use and avoid any damages to the optical fiber during installation

- 5. Single holed(preshrunk)ends eliminates improper fiber threading

- 6. Smooth,deburred stainless steel reinforcing member ends decrease the risk of fiber damage during installation

- 7. Extended liner length prevents contact between the fiber and ther backbone

Unique Features and Benefits

- Pre-shrunk heat bonded assembly

- Single opening for the fiber prevents incorrect assembly

- Adhesive liner creates an environmental seal

- All protector sleeves are RoHS and REACH Compliant

- Over 20 years experience of manufacturing splice sleeves

- Large range of standard sizes and types available

- Custom products designed and manufactured

- Over 2 million splices held in stock for immediate delivery

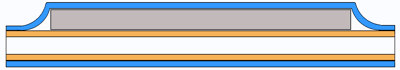

Construction

Our fiber optic fusion splice protector sleeves are manufactured pre-shrunk in a heat-bonded assembly that consists of three components:

- An inner tube of hot-meltable adhesive

- An outer of heat-shrinkable tubing

- A reinforcing strength member

The hot-melt adhesive inner tube bonds to both the fiber and the heat shrinkable outer tube to encapsulate the fusion splice joint and provides vibration damping and an environmental seal, protecting the fiber from damage and contaminants.

The outer high quality irradiation cross-linked polyolefin heat shrinkable tubing provides an instant shrink-force and drives the adhesive liner into all areas of the splice and excludes all the air.

A choice of strength member (stainless steel, ceramic or non-metallic) provides additional rigidity to prevent misalignment, micro bending or breakage of the fiber. Flexible pinless splice sleeves are also available.

The complete assembly is pre-shrunk, providing a heat bonded assembly. This guarantees the sleeve components will not move or come apart during shipping or during installation.

Our pre-shrunk design also provides the advantage of just one aperture, the inner tube that is visible at each end of the splice sleeve. This single opening provides greater assembly accuracy and repeatability and prevents the misplacement of the fiber.

Our fiber optic fusion splice protector sleeves are compatible with all splice sleeve ovens and trays. Custom sizes and lengths can also be manufactured to customer’s specification.

Approvals

The splice sleeves and the materials used are manufactured in an ISO9001:2008 accredited environment.

| Fiber Optic Fusion Splice Protection Sleeves | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||